Call Us

+60146641481

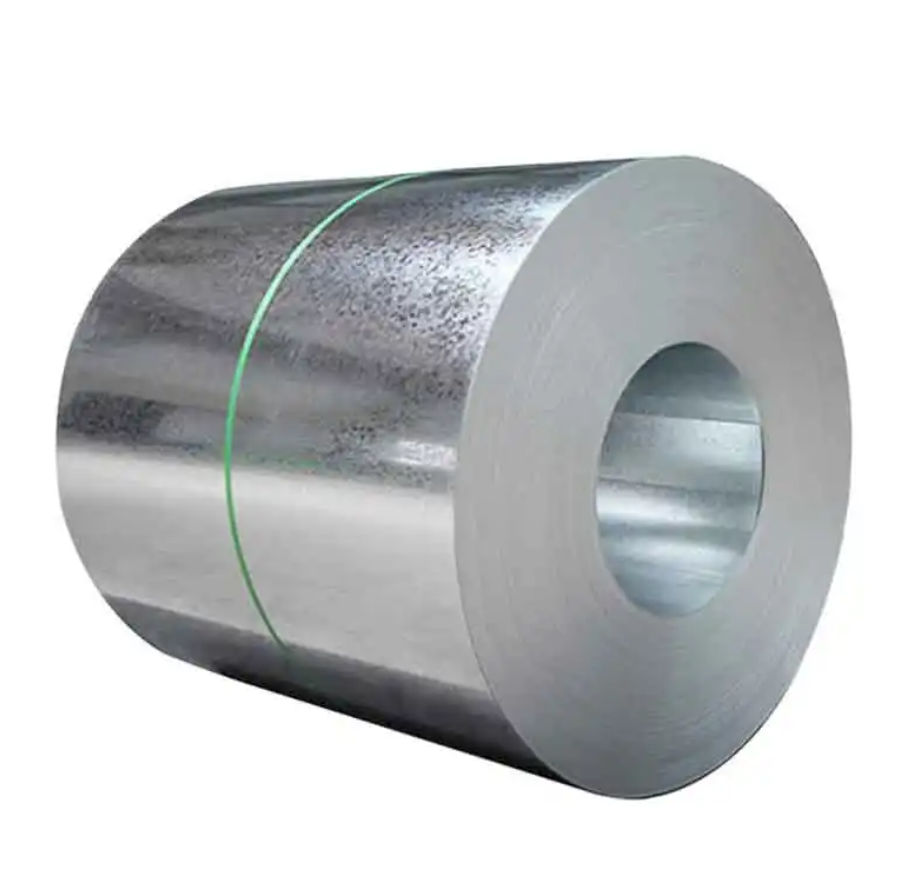

SPCG Galvanized Steel Coil

85.00 - 185.00 USD ($)/Ton

Product Details:

- Chemical Composition SPCG Galvanized Steel Coil

- Product Type Steel

- Material Calcium

- Shape Mine

- Purity 100

- Moisture 05

- Dimension (L*W*H) 20-2500mm Centimeter (cm)

- Click to view more

X

SPCG Galvanized Steel Coil Price And Quantity

- 85.00 - 185.00 USD ($)/Ton

- 1 Ton

SPCG Galvanized Steel Coil Product Specifications

- SPCG Galvanized Steel Coil

- Steel Color

- 100

- 05

- Steel

- 20-2500mm Centimeter (cm)

- Calcium

- Mine

SPCG Galvanized Steel Coil Trade Information

- USA

- Telegraphic Transfer (T/T) Western Union Letter of Credit at Sight (Sight L/C)

- 500 Ton Per Week

- 7 Week

- Sample costs shipping and taxes has to be paid by the buyer

- As buyers requirements

- Middle East South America Eastern Europe

- All India

Product Description

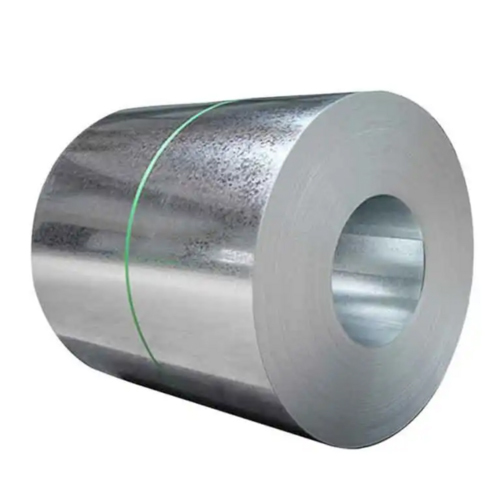

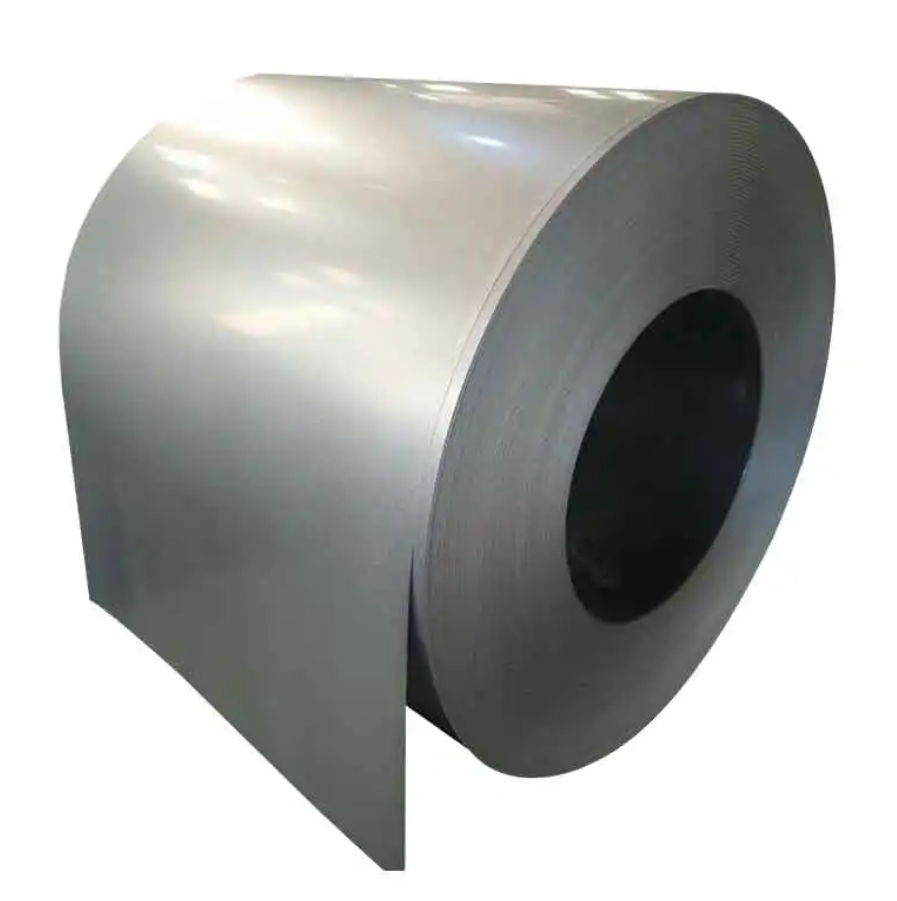

The SPCG designation is a specific classification within the galvanized steel coil family. It signifies that the steel used in the coil has undergone additional processing to achieve specific mechanical properties and surface qualities. This classification ensures that the SPCG galvanized steel coil meets certain standards and specifications, making it suitable for specific applications.

FAQs:

Q: What are the benefits of using SPCG galvanized steel coil?

A: SPCG galvanized steel coil offers several benefits. Firstly, the galvanized coating provides excellent corrosion resistance, protecting the underlying steel from rust and other forms of corrosion. This makes SPCG galvanized steel coil suitable for outdoor applications or environments with high humidity. Additionally, the zinc coating provides a barrier against scratches and abrasions, further enhancing the durability of the steel. SPCG galvanized steel coil is also highly versatile, finding use in industries such as construction, automotive, manufacturing, and more.

Q: What are the common applications of SPCG galvanized steel coil?

A: SPCG galvanized steel coil finds widespread use in various industries and applications. It is commonly employed in the construction sector for roofing, siding, structural components, and ductwork. In the automotive industry, SPCG galvanized steel coil can be found in the manufacturing of car bodies, chassis components, and underbody parts. It is also used in the manufacturing of appliances, HVAC systems, electrical enclosures, and a range of other industrial applications.

Q: How is SPCG galvanized steel coil made?

A: SPCG galvanized steel coil is produced through a process called galvanization. In this process, the steel coil is immersed in a bath of molten zinc or subjected to an electroplating process. The zinc coating adheres to the surface of the steel, providing a protective layer. The coil is then cooled and processed further to meet the specific mechanical properties and surface qualities required for the SPCG classification.

Q: Can SPCG galvanized steel coil be painted or coated?

A: Yes, SPCG galvanized steel coil can be painted or coated with additional layers of paint or protective coatings. However, it is important to ensure that the surface of the galvanized steel is properly prepared before applying any coatings. This may involve cleaning, degreasing, and using appropriate primers or surface treatments to ensure proper adhesion of the paint or coating.

Q: How do I maintain SPCG galvanized steel coil?

A: Proper maintenance of SPCG galvanized steel coil involves periodic inspection, cleaning, and addressing any signs of damage or corrosion. Regular cleaning with mild soaps or detergents can help remove dirt and debris. It is important to avoid abrasive cleaners or harsh chemicals that may damage the zinc coating. If any areas of the zinc coating become damaged or corroded, they should be repaired promptly to prevent further deterioration.

Enter Buying Requirement Details